function of ball mill in the latex compounding

Aqueous Dispersions of Latex Compounding

2016.9.17 This study presents the effect of ball milling on size and stability of aqueous dispersions of latex compounding ingredients such as china clay, zinc diethyldithiocarbamate, zinc 2-mercapto...

More

Ultrafine calcium carbonate-filled natural rubber latex film ...

2019.9.12 This result indicates that ultrasonic/ball mill method can prevent agglomeration formation and provides a good dispersion of CaCO 3 into latex

More

Formulation for natural rubber latex compounds

Ball mill is widely used for preparing the filler dispersion for NRL compound ingredients, whereas ultrasonic has been used in industries to improve the dispersion of nanofillers in...

More

Details of latex compounding ingredients - ResearchGate

Milling constraints include time duration of milling, ball size, the ball-to-sample content proportion, rotation speed, and energy that took part in a vital part of the structure-property ...

More

Latex compounding ingredients SpringerLink

The purpose of this chapter is to review some of the more important compounding ingredients which may find their way into latex compounds. There are a large number of

More

Preparation of Natural Rubber Composites with High Silica

2022.3.1 Ball milling was adopted for preparing the silica dispersion because it has a simple structure, is easy to operate, and is a low-cost process that can be easily scaled

More

Effect of combination ultrasonic and ball milling techniques of ...

The ball milling process is the conventional meth od of preparation of dispersions and ultrasonic has successfully used in preparation of nano fillers such as carbon nanotube

More

Ball Mill - an overview ScienceDirect Topics

The ball mill is used for the grinding of a wide range of materials, including coal, pigments, and felspar for pottery, and it copes with feed up to about 50 mm in size. The efficiency

MoreArticle aléatoire

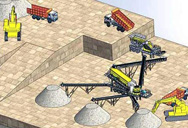

- ROBO unité de traitement de SAND

- concasseur zenith a vendre

- contact du revendeur de concasseur a cne en inde

- meilleur broyeur de Calcite de bois pour faire

- deux images broyeur à cylindres

- occasion machine de fabrication de sable en Nouvelle Caldonia

- Afrique concasseur de pierre mobile haute glimingne

- pays de produit de la bauxite

- Prix de la table commerciale superieure broyeur humide

- arc équipement de pulvérisation

- pièces tungstène concasseur

- pas de décharge concasseur

- matériel de laboratoire des sols

- scories usine de traitement par pulverisation

- récolteuses en trois roues

- rotor double marteau ensemble de concasseur dessin

- concasseurs de roche pulvérisateur Indonésie vendre

- rapport sur le projet de broyeur total indonesie

- hy rouleau tech composants de l usine co

- carbonate de calcium tapis

- types de concasseurs cimenterie

- Fabrique en Allemagne concasseurs de pierres

- cm 4201 broyeur à marteaux de hårga

- S Un Broyeur De Pierre Mobile

- acheter la machine de cuivre du minerai de concasseur tanzanie

- carrières de calcaire tableau

- producteur laitier de concasseur

- machine e de minerai de fer adoptée dans européen

- marge de concasseur de pierre entreprise d exploitation

- broyeur comprennent alpine alpine