curved coal conveyor belt design

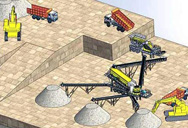

Conveyor Belt Solutions for every mining task

2020.4.14 We provide a wide range of conveyor belts and related products, longtime experience, comprehensive technical and project management expertise and technical

More

CONVEYOR HANDBOOK - hcmuaf.vn

2013.9.17 Design considerations affecting power demands, belt curves, transitions etc., are provided. The layout of this manual and its easy approach to belt design will be

More

(PDF) Conveyor belt technique design and calculation

2023.11.3 Conveyor belts have been used for decades to transport bulk and unit loads. They have proved their worth everywhere because belt conveyor installations can

More

Design of Coal Conveying Belt Correction Device Based on

2023.10.22 Therefore, a design method for coal conveying belt correction devices is proposed in this paper based on fault tree analysis (FTA), quality function deployment

More

Research on Automatic Deviation Correction Device and

2022.12.19 This paper designed an automatic deviation correction device and control system to prevent the belt deviation in the curve section. First, the mechanical structure

More

Selection and Design of Long-distance Large-capacity

2018.7.31 In order to adapt to the ever-increasing complex transportation conditions of slopes, this paper takes practical engineering examples as an example to study the

More

Suspended belt conveyor design (Ivchenko et al.,

Data grouping was performed based on real signals obtained from scanning conveyor belts with the DiagBelt+ diagnostic system. The belt loops on eight conveyors in one of coal mines in...

More

JOSE MARIN, ERIEZ, USA, OUTLINES HOW

2018.9.5 higher‑capacity conveyors for the efficient and controlled movement of coal. In many cases, as belt technology improves, these conveyors traverse challenging

More

DESIGN, ANALYSIS AND OPTIMISATION OF BELT

2021.8.5 The design involves Fatigue Cycle Analysis, Load/Weight Optimization, Static Analysis and Vibration Analysis. Procedure for selecting the optimum material

More

The Complete Guide to Industrial Conveyor

2023.8.22 The chart above illustrates the distance/length requirement for the level of incline on an inclined conveyor. In addition to a lower profile, the “L” and “S” configurations of the steep incline conveyor allow it to

More

The Technology Behind One of the World’s

2018.9.1 About 7,000,000 metric tons are transported to two power plants, using a 30-km-long conveyor system. The first 15-km conveyor—Yubei Section A—starts from the Yubei coal base and ends

More

Chute Design Essentials – How to Design and Implement

centrally loaded, the conveyor hood must be equipped with an adjustable impact plate or curved trajectory plate, in order to deflect the material stream into the desired path. Purpose Height (min) Width (min) Observation 300 mm 250 mm Servicing belt cleaners, sprays, etc. 300 mm 350 mm Liner replacement 450 mm 600 mm Maintenance personnel ...

More

Conveyor Belt Solutions for every mining task

2020.4.14 echnical solutions for all conveying issues. ContiTech produces a variety of high-quality products including steel cord belts, e.g. STAH. ld service – ground application24/7to 10,000 Newton per mm belt width or shortly N/mm (St10,000), and fabric belts, e.g. CONTIFLEX® with a nominal br.

More

Phoenix conveyor belts design fundamentals - Academia

P H O E N I X C O N V E Y O R B E LT S Y S T E M S Phoenix Conveyor Belts Design Fundamentals 왘 New DIN 22101 Phoenix Conveyor Belts Design Fundamentals Hamburg 2004 Phoenix Conveyor Belts Design Fundamentals PHOENIX CONVEYOR BELT SYSTEMS GMBH Hannoversche Strasse 88 D-21079 Hamburg, Germany Internet:

More

Belt Conveyor Design Guide: Quick Tips and Handbook

2024.5.6 In this section of the Belt Conveyor Design Guide, we explore the foundational concepts laid out in the belt conveyor design handbook pdf. This handbook serves as a critical resource, offering in-depth explanations of the mechanical and structural aspects of conveyor systems. It includes detailed information on design parameters,

More

Design of Coal Conveying Belt Correction Device Based on

2023.10.22 The belt conveyor is a key piece of equipment for thermal power plants. Belt mistracking causes higher economic costs, lower production efficiency, and more safety accidents. The existing belt correction devices suffer from poor performance and high costs. Therefore, a design method for coal conveying belt correction devices is proposed in this

More

Conveyor Belt System Design: Best Practices, Types, and

2024.3.19 The basic knowledge of conveyor belt system design encompasses understanding the components, mechanics, and dynamics that make up a conveyor system. This includes the belt material and structure, pulleys, motors, idlers, support framework, and control systems. Each of these elements plays a pivotal role in ensuring the conveyor

More

CONVEYOR HANDBOOK - hcmuaf.vn

2013.9.17 630 to 2000 kN/mLow elongation, high str. ngth, low-weight.Used on high-tension applications and on eq. ipment conveyors.PN belting comprises the vast majority of plied fabric belting in service and is referred to through. ut this handbook. For information advice on other belting types cons. 1 - 2.

More

ABSTRACT 1. INTRODUCTION

2023.4.11 MODERN ORE TRANSFER CHUTE BELT FEEDER DESIGNS DEVELOPED FROM DISCRETE ELEMENT MODELING (DEM) Lawrence K. Nordell, President Conveyor Dynamics, Inc. 1111 West Holly Street, Suite A, Bellingham, Washington 98225 Telephone: 360-671-2200 FAX: 360-671-8450 E-mail:

More

Construction and Maintenance of Belt Conveyors for

2018.4.27 6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angle.

More

Curved conveyors: All you need to know - Ammeraal Beltech

2023.5.4 Curved conveyors are used in many industries like logistics, food, tyre, and building materials. They change the direction of product flow without changing its orientation. However, designing curved conveyors involves several critical aspects to make them function properly and efficiently. In this article, we’ll look at their design and ...

More

Belt Conveyors - Components, Types, Design,

2023.2.16 The design of the frame is an important part of the design of a conveyor. If the frame isn’t made well, it can: ... Curved Belt Conveyor. This conveyor has a frame that is already bent, so it can carry items

More

Overland (Surface) Conveyor Systems West River Conveyors

4 天之前 Take control of your haulage operation with a proven conveying solution custom-built for your process, product, and environment. At West River Conveyors, we build industry-leading overland conveyors custom-designed to your needs. Fabricated from heavy-duty steel and quality components, our systems outperform and outlast other

More

Design of Coal Conveying Belt Correction Device Based on

2023.10.22 The belt conveyor is a key piece of equipment for thermal power plants. Belt mistracking causes higher economic costs, lower production efficiency, and more safety accidents. The existing belt correction devices suffer from poor performance and high costs. Therefore, a design method for coal conveying belt correction devices is proposed in this

More

Design, Analysis and Optimisation of Belt Conveyor for

2022.3.8 CONCLUSION: This project focuses on the design and optimization of the belt conveyor. Theoretical evaluation of the belt conveyor was performed and the capacity of the of the belt conveyor, total belt tension, minimum motor conveyor power and maximum torsion shear stress was obtained as 31 TPH, 4190 lbs., 4 Hp and 400 lbf/in2respectively.

More

Helix DeltaT Conveyor Design

Design and Analyze Belt Conveyors quickly and easily. Learn more. Helix Delta T Online Conveyor Software View Pricing Draw and Calculate Conveyors ... This Demo shows a very long overland coal conveyor with 5 drives and a brake. This is a good demonstration of the Viscoelastic calculation method and is an advanced conveyor design.

More

Coal Industry Conveyor Coal Conveyor Products - ASGCO

Total world consumption of marketed energy is projected to increase by 57 percent from 2004 to 2030. Coal’s share of total world energy use climbed from 25 percent in 2003 to 26 percent in 2004 and is expected to increase to 28 percent by 2030. ASGCO offers a full line-up of conveyor products for the coal industry.

More

Innovations in Underground Coal Mining Conveyor Belt

2024.3.14 Underground coal mining conveyor belts play a pivotal role in the efficient extraction and transportation of coal in mining operations. These belts are the lifelines of the mining industry, facilitating the smooth flow of coal from the depths of the earth to the surface. The inception of conveyor belt technology in mining dates back to the late ...

More

Design of material conveying by variable pipe conveyor

The design of material conveying by the conceptual solution of variable pipe conveyor is calculated on the modelled situation of fly ash transport to the landfill. The present paper is a part of research grant projects VEGA 1/0063/16,

More

Selection and Design of Long-distance Large-capacity

2018.7.31 Jixiu Xu a, Mengchao Zhang b, * School of Shandong University of Science and Technology, Qingdao, China. a2289856231@qq, b, * 1521229044@qq. Abstract: According to the actual engineering example, this paper determines the design scheme by selecting the design of the conveying line, conveyor

More

Coal Mine Conveyor Belt Systems Choose and Purpose

2024.6.5 Moreover, the structured and enclosed design of conveyor belts helps to contain coal dust, which is a common hazard in mining environments. Cost-Effectiveness. Coal mine conveyor belts also offer significant cost savings. The automation of coal transportation reduces labor costs and the need for multiple handling equipment.

More

PIPE / TUBE CONVEYORS A MODERN METHOD OF COAL

2016.2.24 Case1 RAi =. 6.2 (6" Diameter Pipe Conveyor) This value of Ai is for Case 1 return belt is the same as the trough belt. Since Case 1 return idlers have eighteen (18) rolls for three (3) panels it follows that Case 2 has twelve (12) rolls, Case 3 has ten (10) rolls and Case 4 has eight (8) rolls: Case 2 RAi =. Case 1 RAi x 12/18.

More

How to design a conveyor system - FEG

2021.2.24 Existing equipment. When deciding how to design a conveyor system we need to fully understand your existing equipment in order to ensure it is fully integrated into the finished design (if required). This includes finding out the manufacturer and understanding existing SCADA/PLC systems. The material being transported.

More

Belt Conveyor System for Coal Handling in a Thermal Power

2024.3.19 Coal handling plays a pivotal role in the efficiency and sustainability of various industries, most notably in thermal power plants and coal mining operations. belt conveyor system for coal handling transport large volumes of coal over long distances efficiently, reducing operational costs.The process of moving coal from point A to point B

More

Curved Conveyor Bends Conveyor Belts - Conveyor Sections

CONVEYOR FRAMES. Belt conveyor curves and belt conveyor merge sections feature a robust design. Conveyor frame depths can sit as low as 170mm, with low output noises. Some belt conveyor curves feature an automatic tension device, which is incorporated alongside a robust guidance system, offering a low maintenance solution in conveyor

More

(PDF) Conveyor Belt Design Manual Prabir Datta

From the idler roll diameter and the nature of the material conveyed the application is considered as medium duty. For a 900 mm wide belt the mass of moving parts from Table 10 is 55 kg/m 3. Calculate the corrected length and the length correction factor. LC = L + 70 = 250 + 70 = 320 m C= LC L = 320 250 = 1,28 4.

More

CONSTRUCTIVE DESIGN OF A BELT CONVEYOR FOR A

Improving conveyor belt safety training through the use of virtual reality. (Master Thesis). State University, Virginia Polytechnic Institute, Virginia. [3] Erkayaoglu, M. (2011). Life cycle assessment of off-highway trucks and belt conveyors for sustainable mining. (Master Thesis). [4] Solak, A. (2016). Belt conveyor design for coal minerals and

More

Step-by-Step Tutorial: Designing a Belt Conveyor in

2024.3.16 In this comprehensive SolidWorks tutorial, I'll guide you through the step-by-step process of designing a Belt Conveyor system. Learn the fundamentals of creating a realistic and functional conveyor model, from sketching the initial layout to adding intricate details. Gain insights into

More

Design and Analysis of Inclined Belt Conveyor System for

2022.4.14 analysis on pulley drive shaft, on components of belt conveyor and its effect. The Belt conveyor used for coal processing industry is considered to have a design capacity is 250 TPH and speed of the conveyor to be 115 ft. /min. Geometrical modelling has been done using Catia V5R20 and finite element analysis is done in Solid works 2018.

MoreArticle aléatoire

- broyeurs à marteaux

- prix complet des usines de broyage en usa

- cuivre concasseur mobile en Nouvelle Caldonia

- la production de chocolat au broyeur Indonésie billes

- molino broyeur à billes 1500 x 4500

- en australie les mines de cuivre

- Moteur De Broyeurs A Boulets

- machines en pierre de concassage

- occasion broyeur Indonésie boulets Algérie

- concassage cone pour les pierres de la construction en Inde

- broyeurs de sable de l'équipement minier

- table de ciment de la productivité broyeurs à billes

- la façon de gérer le site de la carrière

- acier inoxydable milieu de broyage

- processus de broyage de la chaux

- concasseurs Indonésie percussion pour le charbon

- développement de la communautNouvelle Caldonia de charbon indonésienne

- roche de concassage de rouleau au canada

- fin de broyeur a boulets types

- boule de Calcite broyeur à diyagram

- broyeur a boulets pour l exploitation minière de cuivre

- broyeur de pierre en Maroc

- jag de moulin de minerai de fer concasseur quipement de

- Concasseur à mâchoires RK643

- equipement de broyage de minerai de sulfure

- Comparaison entre le rouleau broyeur vertical vs broyeur à boulets

- plantes concasseur à madhya pradesh

- concassage prix de l'equipement en Nouvelle Caldonia

- concasseurs de pierre en tunisie

- jetable en plastique machine de concassage