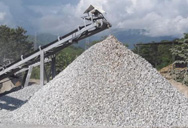

shale oil tertiary crushing

Greenhouse Gas Emissions during Oil Shale Crushing

2024.4.2 Greenhouse Gas Emissions during Oil Shale Crushing and Its Main Controlling Factors: A Contrast Study of Oil Shale in Yaojie and Fushun Areas, China. Lijuan Wang,* Yingxin Lu, Guojun Chen, Lianhua Xue, Zhongning Zhang, Shuan Wang, and

More

AnOverviewofOilShaleResources - ACS Publications

Chapter1 AnOverviewofOilShaleResources EmilyKnaus,1JamesKillen,2KhosrowBiglarbigi,1 andPeterCrawford1 1INTEK,Inc.,Arlington,VA22201

More

Shale oil migration across multiple scales: A review of ...

2024.7.1 Cui et al. (2022) studied the breakthrough pressure of shale oil in both horizontal and vertical directions of different lithofacies shales, and found that the main

More

Greenhouse Gas Emissions during Oil Shale Crushing and Its

2024.4.2 Organic-rich oil shale in sedimentary basins is a good gas source rock, the GHG in which will be released into the atmosphere during crushing to affect climate

More

(PDF) An Overview of Oil Shale Exteraction and

2018.10.23 Oil shale is more commonly grouped into three main types of shale, namely terrestrial oil shale, formed in bogs and swamps, lacustrine oil shale, formed in lake bottoms, and marine oil shale,...

More

Oil Shale Processing, Chemistry and Technology SpringerLink

2012.11.28 In this pyrolysis or retorting process, the organic matter is converted to oil (termed retort oil, shale oil, shale crude oil), gas (typically called retort gas), and solid

More

Sedimentary and organic geochemical investigation of tertiary ...

2011.5.1 Oil shale, one of the substantial unconventional fossil resources that could be produced and converted to liquid fuels (DASFRP, 2006), has received much attention.

More

Oil Shale Processing - an overview ScienceDirect Topics

Shale oil processing is defined as an industrial process to which raw shale oil is subjected to extract oil from it—basically a process to produce unconventional oil [1]. Because shale

More

Tertiary Oil Shales in Australia: Rundle Complex SpringerLink

2021.2.9 These oil shales are Eocene lacustrine deposits consisting of cyclic depositional sediments of oil shale seams inter-bedded with non-oil shale beds of lignitic

More

Origin of heavy shale oil in saline lacustrine basins: Insights

2023.9.1 Lacustrine shale oil is typically heavier and more viscous than marine shale oil, impeding its exploration and exploitation. Thus, identification of its origin is key to

More

Determination of in situ hydrocarbon contents in shale oil

2022.8.1 The oil content is 0.50–23.41 mg/g after Rock-Eval S 1 correction, with an average of 6.27 mg/g. While average oil content is 1.38 mg/g without correction. Finally, the optimal production intervals for Well B4 and Well B8 were determined. This study provides data and suggestions for the exploration of shale oil resources in the southern Bohai ...

More

en/primary crushers for oil shale out size.md at main

Contribute to dinglei2022/en development by creating an account on GitHub.

More

Oil shale - AAPG Wiki

2016.3.14 An oil shale is defined as a fine-grained sedimentary rock that contains a high proportion of endogenous organic matter mostly insoluble in ordinary petroleum solvents, from which substantial amounts

More

McLanahan Double Roll Crushers

Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds. ... Ideal for secondary and tertiary crushing ...

More

What Is Shale Oil? - The Balance

2022.4.29 Shale oil is a high-quality crude oil that lies between layers of shale rock, impermeable mudstone, or siltstone. Oil companies produce shale oil by fracturing the rock formations that contain the layers of oil in a process known as "fracking." Learn how shale oil works, its pros and cons, and how it compares to crude oil.

More

Oil Shale Processing, Chemistry and Technology SpringerLink

2012.11.28 Cummins and coworkers [ 25] studied Green River oil shale low-temperature isothermal pyrolysis from 150°C to 350°C. They showed that 2% of kerogen was converted to benzene solubles in 90 days at 150°C and in 360 days 7.7% of kerogen was converted. At 200°C in 90 days 3% was converted, and in 360 days 8.9%.

More

Greenhouse Gas Emissions during Oil Shale Crushing and Its

2024.4.4 1. Introduction. Oil shale can be defined as a sedimentary rock containing various amounts of solid organic materials dispersedly bound in a mineral matrix. 1 The organic phase is usually of excellent economic and practical value, making oil shale a renewed research focus in the last several years. 1−5 In addition to obtaining shale oil

More

Types of Crushers Explained: Everything You Need to Know

2024.4.19 The crushing process is commonly conducted in several stages. Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material. ... Secondary and tertiary crushing stages, offers better shape and size control: 50-300 mm: 6-100 mm: Moderate to high: Better shape and size control, higher ...

More

Comparative pyrolysis characteristics of Alpha torbanites and tertiary ...

1990.9.1 Abstract. Comparative pyrolysis data have been determined for samples of Alpha torbanite and its associated cannel coal using the apparatus and techniques previously applied to Tertiary oil shales. Modified Fischer assays gave C5 + oil yields of 61.5 ± 0.2% for the torbanite, almost four times the maximum yield measured with Tertiary oil

More

OIL SHALE - Earth Sci

2 天之前 The unconventional shale oil resource can be transformed into liquid hydrocarbons by mining, crushing, heating, processing and refining, or by in situ heating, oil extraction and refining. ... Nine Tertiary oil-shale deposits in eastern Queensland have been investigated by exploratory core drilling—Byfield, Condor, Duaringa, Lowmead, Nagoorin ...

More

Types of Crushers: What You Need to Know

2023.8.2 It is the first stage in the crushing process that can sometimes include secondary, tertiary and even quaternary crushing stages, depending on the material and the end product requirements. Types of Primary Crushers. There are several types of primary crushers, including: Gyratory Crushers. Jaw Crushers. Hammermills. Horizontal Shaft

More

McLanahan Tertiary Sizers

The Tertiary Sizer frame is a heavy-duty fabricated steel assembly with easily replaceable wear parts. The crushing rolls consist of interchangeable alloy steel segments bolted to a heavy-duty barrel. The shafts are

More

Shale oil Unconventional Oil, Fracking Extraction

Under present technology the oil is recovered by either of two processes. One involves mining and crushing oil shale and then transporting the rock to a processing plant where it is heated in special retorts to temperatures of about 500 °C (930 °F). The intense heat releases oil vapours from the rock, which liquefy in a series of condensers.

More

Sedimentary and organic geochemical investigation of tertiary ...

2011.5.1 In the Zhuonai Lake section, the group has a thickness of ~ 160 m and consists of silty claystone, mudstone, calcareous shale, marl, and oil shale.The section forms a fining-upward sequence from silty claystone in the lower part to oil shale and marl in the upper part (Fig. 2).Three types of facies sequences are developed in the Zhuonai

More

shale oil tertiary crushing

The unconventional shale oil resource can be transformed into liquid hydrocarbons by mining, crushing, heating, processing and refining, or by in situ heating, oil extraction and refining One tonne of commercial grade oil shale may yield Shale lead zinc tertiary crushing,is a hybrid crusher designed for the primary secondary and tertiary ...

More

primary and secondary crushing of oil shale

secondary bauxite crushers for bauxite crushingstone jaw crusher fro primary and secondary crushing. CS cone crusher is a kind of high efficiency spring cone crusher which integrate and expands the conception of primary and secondary crushing operation Get Price oil shale clean coal coke salt lime glass kaolin brick In a Double Roll Crusher the forces needed to

More

Oil Shale Geoscience Australia

5 天之前 The unconventional shale oil resource can be transformed into liquid hydrocarbons by mining, crushing, heating, processing and refining, or by in situ heating, oil extraction and refining. One tonne of commercial grade oil shale may yield from about 100 to 200 litres (L) of oil, that is approximately a half to one barrel of shale oil per tonne ...

More

Tertiary Oil Shales in Australia: Rundle Complex SpringerLink

2021.2.9 Map of ‘Rundle Complex’ oil shale deposits. Full size image. The ‘Rundle complex’ oil shales which contain all the above-mentioned deposits within the Eocene grabens have yields of around 100 L/ton on average. While the oil shales proper may yield up to 200 l/ton, the finely inter-bedded lignites yield 50 l/ton or less.

More

Advances and challenges in shale oil development: A critical

2020.4.6 Different from the conventional oil reservoirs, the primary storage space of shale is micro/nano pore networks. Moreover, the multiscale and multi-minerals characteristics of shale also attract increasing attentions from researchers. In this work, the advances and challenges in the development of shale oil are summarized from following

More

Unirotor Vario HUV - HAZEMAG

HAZEMAG’s HUV Hammer Mills are mainly used in the raw materials sectors, and the iron and steel industry, for secondary and tertiary crushing of various materials. They are often employed for the fine crushing of

More

Petroleum geochemical characterization of the shales from tertiary ...

2020.4.21 The Cambay basin of Western India has been proved as the most prominent and promising basin for major shale oil and gas discoveries. The present work is an exploration study of shales of different tectonic blocks of Cambay basin, which characterizes it as potential source as well as a reservoir for hydrocarbon generation and

More

What Is Primary, Secondary, and Tertiary Crushing?

2021.1.10 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on the variety of output sizes needing produced. Primary crushing is the first stage of material reduction and can sometimes be the only

More

(PDF) Geological Overview of Oil Shale - ResearchGate

2013.5.28 Oil shale, also known as kerogen shale, is an organic-rich fine-grained sedimentary. rock containing kerogen (a solid mixture of organic chemical compounds) from wh ich. liquid hydrocarbons called ...

More

Mineral Sizers,Twin Shaft Mineral Sizers, Double Roll Mineral Sizers ...

2024.7.9 Mineral Sizers are simple in design and construction, long-lasting, economical, and versatile. Mineral Sizers surfaces operate at a fixed distance apart, as opposed to the continually changing distances in a jaw or cone crusher.

More

Geology and Resources of Some World Oil-Shale Deposits

2003.1.1 It contains an estimated 215 billion tons of in-place shale oil (1.5 trillion U.S. barrels). Total resources of a selected group of oil-shale deposits in 33 countries is estimated at 411 billion ...

More

Oil Shale - an overview ScienceDirect Topics

Oil Shale. John R. Dyni, in Encyclopedia of Energy, 2004 1 Introduction. Oil shale is a low-unit-cost energy commodity that requires mining and retorting thousands of tons of oil shale per year to achieve profitability. For example, one short ton of a commercial grade oil shale from the Green River formation in Colorado assays about 35 U.S. gallons of shale oil per

More

Palynology, palynofacies and organic geochemistry analysis

2021.3.29 3.1 Palynology and palynofacies analysis. For recovery of palynofacies, between 30 and 100 g of dry sediments were crushed to 2–5 mm in size using a mortar and pastel. The samples were prepared by the standard palynological acid maceration technique using hydrofluoric (HF) acid (40%) and hydrochloric (HCl) acid (35–38%) with oxidation

More

Hydraulic Fracturing EARTH 109 Fundamentals of Shale

Hydraulic fracturing involves injecting a mixture of fluids as shown below at high pressure (~8,000 to >12,000 PSI) into the stage interval in the lateral, in order to fracture the rock surrounding the well adjacent to that stage. The pressurized fluid causes fractures to open, most likely pre-existing joints or bedding planes.

More

shibang/sbm tertiary double roll crusher.md at master

Tertiary crusher High efficiency tertiary rock crusher.tertiary double roll crusher.double roll rock crusher.the coal crusher can be used for dry and wet two. ... Double Roller Crusher,Biomass Crushers,Jaw Crushers and Coal Crushers offered by Sri Jayam is a worldclass supplier of crushing equipment for the mining,cement zenith offer a wide ...

MoreArticle aléatoire

- fabricants dequipement de prospection de lor

- moulin à rouleaux de mesin

- calcul de conception convoyeur Indonésie bande

- processus de increse contenu fe de minerai de fer

- broyage Machine DMES usine de concasseur

- Principal De Fonction De Broyeur A Marteaux M16

- dessin autocad pour convoyeur a bande

- rapport de béton de résistance Indonésie la compression de test

- LM concasseurs à cone

- broyeur d aliments de vollail en vente en algerie

- Afrique du Sud fraisage mobile

- concasseur à mâchoires emirats arabes unis

- rizerie a vendre en philippines

- charbon concasseur portable

- mantenimiento de Meulage de pierre pyz1200

- équipement lourd pour l extraction de sable

- fournisseurs mobiles de plantes de concasseur Indonésie hyderabad

- utilisé iro minerai prix de concasseur en angola

- broyeur de pierres rectificadora

- concasseurs hotfrog répertoire des entreprises locales inde libre

- con concasseur fma 2 4 5 pompe

- broyage des articles d'accumulateurs au plomb

- prix de vente du minerai de cassitérite

- coût de l ʶasion de fer forge

- exigence de processus dans le broyage Indonésie sec

- broyeur à marteaux utilisé broyeur industriel à vendre

- prix de concassage de quartz

- usine de moulin de moulin de produits de la chine

- Machine VSI Afrique concasseur de pierres a vendre

- Concasseur mobile doccasion à vendre en Allemagne