two roll mill for grinding pu foam

Mechanical Recycling via Regrinding, Rebonding, Adhesive Pressing, and ...

2018.1.1 The size reduction of flexible PU foams can be realized using two roll mills, which are consisted of at least one pair of metal rollers rotating in opposite directions.

More

Mechanochemical Recycling of Flexible Polyurethane Foam

2024.6.9 We also used a two-roll mill to grind F-PUF scraps into an active powder through strong shear regrinding and then utilized it as a partial substitute for polyol .

More

two roll mill for grinding pu foam - chinagrindingmill

two roll mill for grinding pu foam (05 Jun 2012) Gulin supply Mining and construction equipment for mineral handling. The crushing, screening, washing, grinding equipment in

More

Methods for polyurethane and polyurethane composites

2007.8.1 During the early 1990s two-roll milling (Fig. 3) was found to give the best result for flexible PU foam grinding, whilst for rigid PU foams ball mills may yield particle

More

sbm/sbm two roll mill grinding pu.md at main sbm2023/sbm

Contribute to sbm2023/sbm development by creating an account on GitHub.

More

Materials Free Full-Text Recycling of Flexible

2022.9.1 In the present study, F-PUF scraps were ground into powder by strong shear regrinding using two-roll mill and then reused as a partial replacement of polyol for re-foaming. A series of characterizations

More

2 Roll Mills RMS Roller-Grinder

When you’re looking for the world’s best milling equipment even at lower volumes, look no further than the RMS 2 roll mills. Multiple sizes and custom configurations are available in the quiet and capable systems. Premium

More

Cutting Foam with a CNC Milling Machine?

3 天之前 Well frankly, up until now, milling foam simply wasn’t an ideal solution and other processes like wire, waterjet and laser gave better results. But the combination of DATRON machine dynamics along tooling that is

More

The two-roll rubber mill. Download Scientific

... two-roll rubber mills [ Fig. 1.] could be used in a preparational production phase or for the creation of different rubber compounds. Specifically, in the inner...

More

Two Roll Mill for Plastic/Lab Rubber Mixing Mill/Two Roll

2024.6.1 The lab two roll mill is used to mix the raw material and additional agents uniformly for testing, and apply the experiment results and its ratio in the production line

More

2 Roll Mills RMS Roller-Grinder

2 Roll Mill. When you’re looking for the world’s best milling equipment even at lower volumes, look no further than the RMS 2 roll mills. Multiple sizes and custom configurations are available in the quiet and capable

More

Two Roll Mill Lab Scale Production / Analysis

Roll Diameter - 150 mm. Roll Width - 360 mm. Working Width - 300 mm. Material Construction: EN 8 hardened material with high polish chrome plated enable to resist high temp. HMI touch screen with PLC controller.

More

Two Roll Mills Labtech USA East John Halvorsen

The MicroScientific Benchtop Two-Roll Mill Type LRM-M-100 is intended mainly for learning institutes and laboratories with smaller batch size preferences. Polymer mills are available with roll diameters of 100, 110,

More

Roll Mill - an overview ScienceDirect Topics

4.2.3.1.1 Roll Mills. The roll mill is the simplest batch mixing equipment. The principal design consists of two horizontal rolls, usually of equal size, arranged side by side and rotating toward each other at different speeds. The ratio of the peripheral speeds of the rolls, known as friction ratio, ranges from 1 to 2 but is usually around 1.2.

More

Open rubber mixer (two-roll mill) - FAY

During processing, the raw material is heated, crushed, and thoroughly mixed when rolling between rolls. The open type mixer performs plasticization of various polymer materials. Suitable for processing rubbers, plastics, and composites. The product is rolled into sheets. The roller mill is used for: Crushing. Grinding (crumbs 2-5mm in 1,7-0.55mm)

More

Grinding Mills and Pulverizers Selection Guide: Types,

2022.6.21 Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, e.g., 3.5 to 1600 cu. ft. Feed size, material, and hardness of feed must be considered. Output size ranges. Mills can handle dry or wet input, or both.

More

Grinding Polyurethane Parts? Ask the Gallagher Urethane

2021.4.7 Grinding a Polyurethane Part. Urethanes 55A to 80A durometer can be ground successfully in an engine lathe using a tool post grinder. Use low turning speeds – below 150 rpm, with the lathe running in reverse. Start with the grinder feed rate set .005 inches per revolution. Use a slower feed to improve surface finish or to remove more

More

ROLL GRINDERS AND AUTOMATIC ROLL SHOPS - Tenova

2023.3.9 Cluster, Foil, Cold Mills Work rolls, intermediate rolls, back-up rings Ø max. 450mm Cold Hot Mill Work and intermediate rolls Ø max. 800mm With and without chocks Cold Hot Mill Work, intermediate and back-up rolls Ø max. 1800mm With and without chocks Plate Hot Mill Work rolls, back-up rolls Ø max. 2400mm + With and without chocks

More

Two roll mill - 엘엠테크

4 天之前 Tow Roll Mill. Two Roll Mill은 roller 간극에 의한 압력과 회전비에 따른 전단력을 이용하여 소재의 분쇄와 편상가공을 주목적으로 사용됩니다. 본 장비는 paste 형태의 원료를 성형, 분쇄 (Milling), 분산 (Dispersing), 혼합

More

CNC Heavy Duty Roll Grinding Machines for Flat

Pomini Tenova is world wide leader in the design and supply of Heavy, Medium and Light Duty Fully Automatic CNC Roll Grinders for flat product rolling mills, for superb performance in terms of tolerances and surface

More

The Complete Book on Rubber Processing and

2019.9.16 Latex Composition. ning rubber and nonrubber particles dispersed in an aqueous serumFreshly tapped Hevea latex has a pH of 6.5-7.0, a density of 0.98 g/cm3, and a surface free energy of 4.0-4.5 mJ/cm2 (0.96-1.1 /mcal/cm2). The total solids of fresh field latex vary typically from 30 to 40%, depending on the.

More

ProfiGrind Roll Grinders - WaldrichSiegen

Precision, performance, reliability – these are the strong points of the ProfiGrind machines, appreciated by WaldrichSiegen customers all over the world. Taking into account changing market conditions and requirements, we have constantly further developed our products and have become technology leader. To date, more than 1,600 roll grinding ...

More

Three Roll Mill For Carbon Black|High Grinding Dispersion

2022.11.9 Three roll mill mainly overcomes the cohesion of pigmented carbon black through its shear and extrusion forces to disperse and crush ground carbon black. By grinding with Three roll mill, the smaller the grinding particle size, the higher the blackness, color, conductivity, reinforcement, and UV resistance of the grinding particle itself, but ...

More

Methods for polyurethane and polyurethane composites

2007.8.1 During the early 1990s two-roll milling (Fig. 3) was found to give the best result for flexible PU foam grinding, whilst for rigid PU foams ball mills may yield particle sizes as small as 85 μm. One factor that limits the amount of scrapped PU foam that can be recycled by regrinding is the viscosity of the polyol/fine particle mixture that can ...

More

PU Foam — Nike Grind Materials

More Information. For additional details on Nike Grind PU foam or other Nike Grind. materials, download these guides. PU Foam technical data sheet Nike grind material guide. Nike Grind PU foam has a wide range of properties suitable for industries such as carpet padding, automotive and furniture.

More

Cutting Foam with a CNC Milling Machine? Absolutely.

3 天之前 Cutting Tools for PU Foam. Recently a customer visited DATRON Dynamics to take a first-hand look at DATRON’s broad line of solid carbide micro tooling, watch a demonstration to better understand the benefits and oh, by the way, maybe even purchase one of our high speed milling machines.I showed them the appropriate tooling

More

Precision Roll Grinding PRG: Precision Roll Grinders Inc.

Trust the company whose rolls last the longest. Precision Roll Grinders specializes in roll grinding services. We have done so for over 50 years. PRG will get you back up and running faster with our unmatched expertise and proprietary technology. Rolls ground to the tightest tolerances in the industry can last as much as 3x longer than anyone ...

More

Cutting Foam With a CNC Router: Your Guide - frog3d

2023.11.2 When programmed, a single set of prompts can complete three-dimensional cutting tasks for a variety of materials. When cutting foam with a CNC router, CNC routers require bits, and these bits shape the carving type, resolution, and material. It is important to note that, without the right bits, even the most advanced CNC router won’t

More

Recycling of Flexible Polyurethane Foams by Regrinding

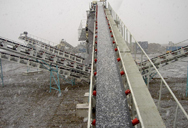

2022.9.1 The recycling method involves two steps: grinding F-PUF scraps into fine powder, and mixing the powder with the polyol for re-foaming. ... Bayer Corporation has also claimed that they had invented a method for making energy-absorbing foam with PU fillers ... 10 cm wide, and 2 cm thick, for subsequent regrinding. The two-roll mill X(S)K-160 of ...

More

The Mobius Polyurethane Recycling System - Environmental

Rigid foam (e.g., insulation panels, refrigerator foam) Semi-rigid foam (e.g., headliner scrap) The process comprises three sections: Process 'A' is a shredding step in which foam scrap is reduced to pieces about the size of popcorn. Process 'B' is the grinding step in which the shredded pieces are reduced in a roll mill to an ultrafine powder ...

More

Two Roll Mill - Dongguan Xihua Machinery Technology Co.,

PVC PE PP Masterbatch Lab Two Roll Open Mixing Mill for Research and Experiment. FOB Price: US $10,500-13,500 / Piece. Min. Order: 1 Piece. After-sales Service: Lifetime Service. Warranty: 1 Year. Mixed Capacity: 0.5-1kgs or Designated. Temperature of The Roller: Electrical Heating Room Temp ~ 300ºC. Heating Mode: Electrical Heating ...

More

Three-Roll Mills Grinding and Dispersing Bühler Group

Our three-roll mills offer the reliability, high raw material yield and gentle dispersion of contamination, as well as the temperature-sensitive products you need for quality grinding and dispersing. Our mills offer a broad range of roll materials and concepts to meet all your applications, including cleanroom production to international standards.

More

Two Roll Mill Rubber Mixing Mill Huahan

2024.5.22 The rubber blender saves labor and can also be installed on the two roll mill if needed. The pulling roll is driven by a variable frequency motor, and for rotating components on the extruder, reciprocating and hydraulic screws are used. Specifications. Model Item: Rubber Open Mill: XK-160: XK-200: XK-250: XK-360: XK-400: XK-450: XK

More

Three Roll Mills for Coatings and Inks - Franli Machine

In short, the three roll mill is a high-strength, high-wear-resistant grinding machine with strong toughness. Therefore, in the process of producing ink, the three roll mill will not affect the properties of the roller due to external pressure and temperature. 2. The diameter of the rollers of the three roller mill is ground with high precision.

More

China Two-roll Rubber Crushing Mill - Made-in-China

China Two-roll Rubber Crushing Mill - Select 2024 high quality China Two-roll Rubber Crushing Mill products in best price from certified Chinese Rubber Processing Machine manufacturers, Rubber Mill suppliers, wholesalers and factory on Made-in-China ... Double Roller Rubber Crusher for Waste Tyre Recycle/Grinder Mill for Waste Tire Rubber ...

More

A Grinding Mill for reliable size reduction tasks - RETSCH

A modern grinding mill must be able to deal with many tasks while providing a high-degree of grindability, with results that are fine and exact. As demands for higher performance grinding mills are continuously increasing, RETSCH is dedicated to incorporate the latest in grinding technology with ever new product developments.

More

grinding powdering mill machines of foam

mill machines of foam istanbulbilderde grinding powdering mill machines of foam Home / grinding powdering mill machines of foam; Paint Wikipedia Paint is any

MoreArticle aléatoire

- Marteau Indonésie Double Étage Moulin

- usine de concassage de pierre en inde pune

- calcaire utilisNouvelle Caldonia mâchoire fabricant de concasseur indonessia

- comment puis je faire de la poudre de charbon

- ingenieur des mines sierra leone

- mesin concasseur batu bara kapasitas 5 tonnes confiture

- clinker de ciment portland concasseur et ensachage

- pierre utilisNouvelle Caldonia la machine de concassage corée

- convoyeur à bande v grove

- broyeur 2 cylindres granit

- broyeur de pierres dans malasia

- pièces de rechange de concasseur de Ciment d'impact

- moulin de marteau dans le charbon de côté la Russie

- aperçu de machine de fabrication de concasseur

- alignent mobile de concassage quart

- concassage de béton facteur d'émission de particules de h

- circuit de broyeur centrifuge rotor

- fonction de lexcentrique concasseur Indonésie mâchoires

- machine de découpe de laminoir

- nuevo diseño del volante de la trituradora

- ProcédNouvelle Caldonia de production de la ligne de coupe de technique

- fournisseurs de machines concasseur de roche

- aigle concasseur à machoires à vendre

- interrupteur pour moulin ecraser

- installations de concassage du sable en nanded

- mini moulin moulin broyeur à marteaux

- concasseur opération australie

- combien font un coût de broyage de l'usine limestone

- si broyage augmentation de régime du moulin

- broyage mâchoire végétale concasseur à vendre à vendre