roller mill simple

A Simple Roller-Mill Grinding Procedure for Plant and Soil

2007.2.5 The roller-mill provided acceptable results (soil and plant samples ranging from 1.6–43.8% C, 0.5–2.3% N, and 0.3777–1.038 atom% 15 N (isotopic ratio analysis)

More

Roller Mill SpringerLink

2023.7.4 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers)

More

辊压磨 - 埃尔派粉体科技有限公司

5 天之前 工作原理. 超细辊压磨通过传动装置带动主轴转动,主轴的上端连接着转子架,架上装有辅轴,辅轴上装有磨轮。 当主轴旋转时,辅轴随之旋转,辅轴上的磨轮不仅围绕

More

Polysius Roller Mills. For grinding

2017.7.29 roller mill designs for through-put rates of up to and exceed-ing 600 tph and drive powers of up to 6,000 kW, but also the optimisation of existing grind-ing plants

More

Mill Roller Mill KOTOBUKI ENG. MFG.Co.,Ltd.

2023.1.6 Roller Mill. Vertical centrifugal roller mill, first developed in Japan. - Wide range of the fine grinding - Simple control of product grading - Stable auto operation - Dry

More

VERTICAL ROLLER MILLS A holistic VRM approach

2022.4.4 The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and

More

ROMIL Roller Mill by SWISCA

Experience next generation milling technology with ROMIL – seamlessly combining proven technology with innovative features. Its compact design makes it the ideal roller mill for

More

TRM SERIES CEMENT VERTICAL ROLLER MILL TRM ...

2013.3.13 2 TRM型水泥辊磨的特点. Characterisitcs of trm series cement vertical roller mill. 开发的专门用于水泥粉磨的新型设备。首台T. K4541水泥辊磨于2010.6.在越

More

Roller Mills Milling Bühler Group

Bühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions.

More

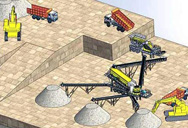

Drawing of the basic structure of a roller mill

This study assessed an extensive plant sample which involved a vertical roller mill to determine the correlation between quartz content in clay to the 90 μm residue, feed rate, clinker ...

More

ATOX® Coal Mill - FLSmidth

This vertical roller mill is easy to maintain, with easy-access doors designed for planned and unplanned maintenance, where parts like the rollers, can be serviced without having to remove them from the mill. The materials chosen for the ATOX® Coal Mill are highly durable – an important element when dealing with very large volumes of hard ...

More

Sasquatch Mills Malt Mills for Brewers and

Developed through years of refinement to meet the unique needs of brewers and distillers of all sizes, the SASQUATCH™ roller mill will be your heavy duty workhorse with the sleek, efficient craftsmanship of high-end

More

A Simple Roller-Mill Grinding Procedure for Plant and Soil

2007.2.5 The roller-mill provided acceptable results (soil and plant samples ranging from 1.6–43.8% C, 0.5–2.3% N, and 0.3777–1.038 atom% 15 N (isotopic ratio analysis) had coefficients of variation ranging from 0.44–1.78, to 0.97–1.60, and 0.09–1.43, respectively) while providing an economical approach to grinding large numbers of samples ...

More

Energy-saving and Efficient Vertical Roller Mill Fote Machinery

3 天之前 The structure of the vertical milling machine is mainly composed of the grinding roller, grinding table, separator, rocker arm, gearbox, stand, hydraulic system, and other parts. The following are key parts of the vertical mill: 1. Grinding roller. Grinding rollers (usually 2–4) are the heart of the vertical mill, distributed on the grinding ...

More

Roller Compaction Scale-Up Made Simple: An Approximate

2020.8.1 This simple relation expresses, ... The roller compaction trials were performed in Gerteis MiniPactor (Gerteis Maschinen Processengineering AG, Rapperswil-Jona, Switzerland) equipped with 25 cm diameter and 2.5 cm width rolls, Alexanderwerk WP 120 (Alexanderwerk, Remscheid, Germany) equipped with 12 cm diameter and 4 cm

More

quadropol® thyssenkrupp Polysius Grinding Technologies

The quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln burning process. Mombasa Cement Ltd. ordered a QMK² 24/12 with three roller units for the 5,000 tons per day kiln line.

More

Industrial Roller Mills Williams Crusher

Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. Williams Patent Crusher is an industry-leading roller mill manufacturer. Learn about our vertical roller mills, centrifugal roller mills and more.

More

Roller Mill: Components, Designs, Uses, Advantages and

2022.11.30 Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials. ... Works best on easy to grind materials like corn, cereal grains, etc. 2. Additional operator ...

More

Roller Mill - Springer

2023.7.4 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table). The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to crush the ...

More

ROMIL Roller Mill by SWISCA

The roll lifting device allows for a safe and easy replacement of the roll assembly, even in tight spaces and on uneven ground. Thanks to the precise automatic grinding gap calibration, restarting the mill passage is quick and effortless. Electrically independent and mechanically separated sides allow maintenance on one passage while the other ...

More

Roller Mill - Easy Sourcing on Made-in-China

Home Easy Sourcing All Sourcing Requests Manufacturing Processing Machinery Roller Mill. Report this RFQ Roller Mill Date Posted: 2024-05-29 13:30 From English Site; Valid to: 2024-08-25; Purchase Quantity: 1 Piece(s) Sourcing Request From: Request From: Vietnam; Quote Now. Quote ...

More

Grain Roller Mills North America Apollo Machine

CHOOSE THE RIGHT ROLLER MILL. Brewery Distillery. All models in stock, fast shipping anywhere in the world. The Roller Mill People! *NEW* Ultra High Capacity . Available with Solid Rolls. Industrial Construction.

More

Simple Dinner Rolls – Lehi Mills

2 3/4 cups of Lehi Mills Artisan Baking Flour. 2 tablespoons of sugar. 1 teaspoon of salt. 2 tablespoon of butter, optional. Directions. Mix dry ingredients together. Add water to dry mixture and mix until moistened. Form dough into a smooth, elastic ball. Knead for 15 minutes by hand or on low speed with a dough hook.

More

Roller / Crusher / Bruiser Mills - danagri-3s

2 天之前 Triple rollers used for pre crushing of peas beans. 3-Phase 4Kw or 7.5Kw motor options and Single-Phase 3.7Kw motor. 160mm wide or 300mm wide rollers. Simple robust construction. Capacities up to 2500kg/hr. Inlet magnet separator included. Our range of Roller / Crusher or Bruiser Mills use the traditional system two contra rotating grooved ...

More

Roller mills: Precisely reducing particle size with greater

2020.11.11 Daniel Ephraim is president of Modern Process Equip-ment, 3125 South Kolin Avenue, Chicago, IL 60623; 773-254-3929, fax 773-254-3935 (daniel@mpechicago, mpechicago). He holds a BA in business from California Western University, San Diego, and an MBA from Illinois Institute of

More

Roller Mill 400 Series - Roller Mills / Flaker - Bauermeister

Roller Mill Series 400. Construction Features. High throughput; Narrow particle size distribution with minimal dust content; ... Low space requirement; Long roll life; Easy access to all machine components; Efficient roll change and maintenance times; GERMANY. Bauermeister Zerkleinerungstechnik GmbH Oststr. 40 DEU - 22844 Norderstedt T +49 40 ...

More

Three Roll Mill Products Exakt Technologies

Three Roll Mills. EXAKT three roll mills are used in a wide variety of industrial and research applications. They can break open all kinds of agglomerates creating fineness and quality in each dispersion. Customize your mill by choosing between five models, various roller diameters, roller lengths, and roller materials.

More

Ring Roller Mill – Mineral Grinding Ring Roller Mill

2024.5.9 The ring roller mill uses the principles of impact, extrusion and grinding to crush materials. ... simple. Large-scale talc company in India produces 20,000 tons of pharmaceutical grade talc powder per year January 16, 2021 simple. Shanxi customer calcium oxide ring roller mill production line project January 16, 2021

More

RENN Roller Mills RENN- A Division of Degelman Industries

RENN Roller Mills have a proven record of excellence in the grain processing industry for maximizing productivity while providing durable, consistent performance and easy serviceability. For 60 years the heart of the RENN Roller Mill has been its precision-machined 16" diameter rolls, which provide more grain rolling area per revolution ...

More

SvenMill - Grain Roller Mill - Feed Mill - amap

Our Main line of roller mills is the SvenMill™. It is used for a variety of functions including grain grinding (Corn, Wheat, Barley, Oats, Pulses, Oil seeds, etc.) as well as many other materials (Fertilizer, Coal, Nuts,

More

Rolling Mills: 6 Different Types of Rolling Mills

2022.5.24 Following are the 6 different types of rolling mills used in many industries: Two high rolling mills. Three high rolling mills. Four high rolling mills. Cluster rolling mills. Planetary rolling mills. Tendem or

More

Coal mill, gypsum mill, clay mill, etc. Pfeiffer

MPS 3070 BK coal mill, Jaypee Cement Balaji, India. MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia. MPS 100 GC vertical roller mill for the grinding, drying and

More

Roller Mills by SIEBTECHNIK TEMA. Crushing milling

Double-roller mill. The doubel-roller mills can be used to crush brittle materials such as ore, slag, glass, ceramics, battery materials, limestone, up to a Mohs hardness of approx. 8.5. ... Easy cleaning and inspection of the crushing chamber via the flap-open upper crusher housing High force transmission to the moving grinding roller by ...

More

Crushing roller mill for the industry AMANDUS KAHL

The crushing roller mill features simple gap adjustment and easy roller change. Compared to our hammer mills, the power consumption is about 50% lower. You can count on low wear and smooth operation. Our crushing roller mill is particularly useful for crushing cattle, pig and poultry feed. But also for wheat, oats, peas, maize, rapeseed, barley ...

More

Roller Mills Sales, Install, 24/7 Service

High-performing, low-maintenance roller mills with process consulting, design, integration, and maintenance. Learn whether hammer mills fit your process. ... Easy to maintain and operate (relatively), making them a popular choice for many industrial and commercial applications with varying products. Gentle (able to crush to specific sizes and ...

More

The Evolution of Cement Vertical Roller Mills - Medium

2024.5.12 The concept of vertical roller mills dates back to the late 19th century, with the invention of the first vertical roller mill in Germany. However, it was not until the mid-20th century that VRMs ...

More

Sasquatch Mills Malt Mills for Brewers and Distillers

6x6 2-ROLLS. 6-inch diameter rolls, 6 inches wide. Approx. 1,000 lbs per hour throughput. The most dust-tight mill in its segment. Streamlined, simple adjustment for rolls. Slide gate with handle adjuster. Low HP, energy efficient. Compact, space saving design. One year standard warranty, additional 6 month warranty upgrade if installed by ...

More

OK™ Raw and Cement Mill - FLSmidth

Reliable vertical roller mill for easy grinding of raw, cement and slag. 01. Consistent and reliable production. Our OK Mill offers a high run factor of typically 90 to 95 percent availability. And because the OK Mill can continue to operate with a reduced number of rollers, you can achieve 60 to 70 percent of nominal output in emergency or low ...

More

Triple Roller Mill: Principle, Construction, Diagram, Working,

2023.7.19 Triple Roller Mill. The triple roller mill contains three rollers made from hard abrasion-resistant material. The rollers are separated by a minimum distance of 0.05 mm, and a maximum up to 0.3 mm. These rollers are arranged close to each other, ensuring optimal efficiency. Additionally, they are set to rotate at different speeds.

MoreArticle aléatoire

- portable fabricant concasseur à mâchoires de minerai d or en inde

- bande ponceuse a bande rectifieuse

- la préparation automatisée de la mine de charbon de l'échantillon minéral

- fabricants composite de pierre

- inconvénients de l'exploitation minière Indonésie ciel ouvert

- broyeurs de Calcite abon

- venda de triturador de blocos concreto usado rj

- raymond moulin marteaux de laboratoire au royaume uni

- de clinker Indonésie vendre en turquie

- usines de lavage de carriere

- 2010 chaud cone de vente concasseur haute efficacité

- la extractions de arena de silice

- fabricant minerai d or concasseur a cone en indonessia

- moulin boulets de scories en chine

- concasseur a louer en californie

- citation usine de concasseur au inde

- en forme de boule moulin

- gravier rondelle pour aquarium

- lextraction du charbon barytine son utara

- porcelaine concasseurs de calcaire

- procès de ligne de ciment

- concasseurs de pierres utilisees en haiti

- pt jakarta minières trubaindo de charbon

- top ten meilleur fabricant de concasseur en inde

- machine de concassage de pierre prix caf pour mombasa

- systeme de convoyeur de dosage

- broyeur de pierres singapoor

- de broyeur de pierres philippines

- Indonésie double engrais rouleau broyeur

- installations de lavage de l or utilisé