vibration monitoring of crusher in coal handling plant

Fault diagnosis of Coal Ring Crusher in Thermal Power plant:

On the basis of several parameters like vibration, leakage of oil, noise, sound etc, faulty conditions of the machine can be predicted. Coal Ring Crusher plays a critical role in

More

(PDF) Vibration Test and Shock Absorption of

2020.10.28 A field vibration test was conducted on the coal crusher chamber of a thermal power plant to evaluate its vibration performance.

More

(PDF) Vibration Test and Shock Absorption of Coal Crusher Chambers

2020.9.15 The coal crusher generates large vibrations when crushing coal blocks, which can affect the equipment itself, as well as the safety of the structure. In order to

More

Operation and Maintenance of Coal Conveying System

2013.1.1 This paper based on our country current coal conveying system in thermal power plant, on the basis of typical screening and crushing mechanical equipment of

More

[PDF] Vibration Test and Shock Absorption of Coal Crusher

2020.10.27 A field vibration test was conducted on the coal crusher chamber of a thermal power plant to evaluate its vibration performance. The vibration displacements

More

[PDF] Vibration Test and Shock Absorption of Coal Crusher

2020.9.15 The coal crusher generates large vibrations when crushing coal blocks, which can affect the equipment itself, as well as the safety of the structure. In order to

More

VibrationTestandShockAbsorptionofCoalCrusherChambersin ...

2023.10.15 machine parameters, the vibration problem for the coal crusher chamber is more prominent in some power plants, whereas other vibrations are very small. is

More

Figure 6 Vibration Test and Shock Absorption of Coal Crusher

Vibration Test and Shock Absorption of Coal Crusher Chambers in Thermal Power Plants (I): Field Test and Assessment. Figure 6. Time-domain waveform: (a) Vertical vibration

More

Development Of Condition Based Maintenance For Coal

2015.10.8 In Coal Handling plant by providing of permanently mounted temperature sensors can continuously monitor Gear-Box of Critical Conveyor, bearings of Crushers.

More

vibration monitoring of crusher in coal handling plant

2018.11.12 Vibration monitoring of crusher in coal handling plant. Vibration monitoring of crusher in coal handling plant Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, Vibration monitoring of crusher in coal handling

More

[PDF] OPERATION AND MAINTENANCE OF

Many utility systems in the world have power plants operating with fossil fuel. In the thermal power plants maximum requirements of fuel is a coal. The handling of this fuel is a great job. To handle the fuel, i.e., coal, each

More

Fault diagnosis of Coal Ring Crusher in Thermal Power plant:

2016.9.1 On the basis of several parameters like vibration, leakage of oil, noise, sound etc, faulty conditions of the machine can be predicted. Coal Ring Crusher plays a critical role in Coal Handling ...

More

Vibration Monitoring Of Broyeur In Coal Handling Plant

2020-05-02T16:05:07+00:00; Vibration Monitoring System for Coal Handling Plant Masibus . 13112021 Button Home; Products Data Acquisition; Controllers AutoTune PID Controller TC5396; Auto Tune PID Controller LC5296VATvibration monitoring system for coal crusher accountscore techniques of Condition monitoring for coal crushers Coal India to hold

More

crusher/sbm coal crusher vibration probe.md at main yunan88/crusher

Contribute to yunan88/crusher development by creating an account on GitHub.

More

Development Of Condition Based Maintenance For Coal

2015.10.8 The coal, which of required size, is not required to crush. To avoid entry of proper size coal in crusher the screens are used. 5.1.4 Stacking and Reclaiming Plant: - After unloading of the coal, required quantity of coal is to be bunkered. The remaining quantity of coal is to be required to store. This store coal can be reclaim as per requirement.

More

Prevention of Fires in Coal-Handling Facilities:

2011.10.28 A proactive approach to fire prevention focuses not so much on detecting smoke, which indicates fire, but rather on monitoring CO, which indicates the potential for fire. Any delay in dealing with the potential for fire only increases the rate of burning. A CO detection system can provide warning of a potential fire up to two days before a ...

More

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011.12.31 Then, the safe operation of coal handling system and the proper method of the equipment maintenance are summed up. Dual drums head actuations Fig.3. Head and tail actuations 1 actuation drums one ...

More

vibration monitoring of crusher in coal handling plant

vibration monitoring of crusher in coal handling plant منزل vibration monitoring of crusher in coal handling plant

More

Fault diagnosis of Coal Ring Crusher in Thermal Power plant:

2016.9.1 In order to increase the efficiency of machine, it is required to measure the faults generated during operation by proper monitoring of the system. On the basis of several parameters like vibration, leakage of oil, noise, sound etc, faulty conditions of the machine can be predicted. Coal Ring Crusher plays a critical role in Coal Handling Plants

More

vibration monitoring of crusher in coal handling plant

imports of coal crusher plant . Coal Handling Plant (CHP) plays an important pivotal role in the smooth The raw coal is hence processed in Primary secondary crushers the size of the Blending of Indian coal with imported coal, if applicable (only for those plants, ... vibration monitoring of crusher in coal handling plant; name and phone number of stone crusher

More

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011.1.1 The process of from big to small .Currently medium-sized power plant coal handling system used in coal crusher, structural characteristics can be divided Hammer, Impact, and other types of hammer ring, hammer coal crusher due to its large strengths, high-efficiency features, used more often. 2.2.1. a Operation and maintenance of roller

More

vibration monitoring system for coal crusher – Grinding Mill

Gulin VSI5X Impact Crusher, VSI Impact Crusher, PE vibration monitoring instruments. TERRALOC 6. Terraloc 6 rugged Davis Derby – Electronic Equipment and Monitoring Systems » Free Online Chat. Spec Coal Handling Plant. VIBRATION MONITORING SYSTEM FOR COAL CRUSHER Vibration monitoring system should be offered for

More

(PDF) Vibration Test and Shock Absorption of Coal Crusher Chambers

2020.10.28 A field vibration test was conducted on the coal crusher chamber of a thermal power plant to evaluate its vibration performance. The vibration displacements and velocities of the structure, coal ...

More

sbm/sbm coal crusher monitor 1.md at master

sbm / sbm coal crusher monitor 1.md. chengxinjia 2567a2622d sbm. 2022-11-03 18:35:50 +08:00. 28 KiB Raw ...

More

(PDF) Noise and Vibration Control in Crusher Plant Activities

2019.4.8 The focus of this study was to look for control strategy for noise and foot transmitted vibration hazards related to fixed machineries in crusher plants. Six crusher plant sites were selected ...

More

Fault diagnosis of Coal Ring Crusher in Thermal Power plant:

In order to increase the efficiency of machine, it is required to measure the faults generated during operation by proper monitoring of the system. On the basis of several parameters like vibration, leakage of oil, noise, sound etc, faulty conditions of the machine can be predicted. Coal Ring Crusher plays a critical role in Coal Handling Plants (CHP) of Thermal Power

More

Quality Assured Maintenance Management For Coal

2015.10.8 Quality Assurance maintenance management, which meets the same requirements for Equipment Reliability, is demonstrated in the ISO 9001:2000 Standard [1]. The process is managed through QMS, which is clear on PDCA as a process method. PDCA is Plan, Do, and Check Act. Most modern maintenance management activities are

More

Stacker Reclaimer Operation And Their Parts

2016.11.13 Stacker reclaimer Bucket wheel are used for reclaiming . The bucket wheel drive either consists of hydraulic system or motor,fluid coupling, brake and gear box, mounted on a drive frame supported by

More

Figure 2 from OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL ...

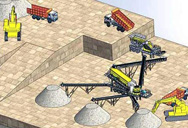

In the thermal power plants maximum requirements of fuel is a coal. The handling of this fuel is a great job. To handle the fuel, i.e., coal, each power station is equipped with a coal handling plant. Maintenance of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job.

More

Effect on Bearings in Rotating Components by Vibration

2019.12.12 Venu Padmavathi G, Diwakar G, Satyanarayana MRS (2011) Vibration monitoring of crusher in coal handling plant of Dr NTTPS. Int J Eng Sci Technol 3(8) Google Scholar Mende E, Rauber TW, Varejao FM, Batista RJ (2009) Rolling element bearing fault diagnosis in rotating machines of oil extraction rigs. Scotland, 24–28 Aug 2009

More

Operation and Maintenance of Coal Conveying System

2013.1.1 Now, coal crusher used in the coal handling system of domestic large and medium-sized power plant, according to their structural features can be divided into hammer type, strike back type and ring hammer type etc., which ring hammer coal crusher is more advanced models, high quality and efficiently fragmentation of anthracite coal, common

More

function of crusher in coal handling system - shibang

Coal mining processing plant in Nigeria. This coal mining project is an open pit mine located in Nigeria, announced by mining company - Western Goldfields - that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US$1.2 billion which could be used for the generation of electric power...

More

VIBRATING GRIZZLY SCREEN FEEDERS

2023.6.17 as option to prevent occurrence of resonance vibrations during stopping operation of the unit. Electronic Vibration Monitoring System can also be offered for on-line condition monitoring of a Grizzly unit in actual operation. Technology and Service IC Grizzly Screen Feeders are made-to-measure solutions which employ the highest level of vibration

More

CRUSHER FOR COAL HANDLING PLANT

Vibration monitoring of coal crusher in coal handling plant of dr NTTPS. Machines of some kind are used in nearly every aspect of our daily lives; from the vacuum Coal handling unit – Stone Crusher MachineGrinding Mill

More

Vibration Monitoring Crusher Coal PDF Bearing

2024.3.16 Vibration Monitoring Crusher Coal - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document summarizes a study on vibration monitoring of a crusher in a coal handling plant. Vibration readings were taken at different points on the crusher and motor using a Data PAC 1500 analyzer. High vibrations indicated

More

(PDF) Effect on Bearings in Rotating Components by Vibration

2019.12.1 Effect on Bearings in Rotating Components by Vibration Analysis: A Case Study in Steel Plant. December 2019. DOI: 10.1007/978-981-32-9931-3_27. In book: Emerging Trends in Mechanical Engineering ...

More

mill/sbm crusher coal handling.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

MoreArticle aléatoire

- pt persadatama lestari charbonnière

- ce est extraction du calcaire

- broyeur de pierres minidi Medan

- pal charbon société fournisseur de concasseur guagaon

- Laminoir A Froid De Cisaillement

- Desain kontruksi mesin concasseur plastik

- Meulage de pierre de cono mexicon delares

- machineries de moulin à farine

- broyeur de sable fournisseur

- 15 tonh de Concasseur à cône

- broyeur Indonésie marteaux 200kw

- Lydenburg minerai de fer

- construction avec utilisNouvelle Caldonia pour

- concasseurs de granit et de l'exploitation miniere

- prix de tapis roulant 0

- modèle de poudre moulin de broyage

- Traitement des bauxites de bas grade

- sélection de Raymond moulin

- rancilio icecrusher 15055 et pièces de rechange

- fabricant de vis de sable en france

- list of fine sand process machine

- liste de toutes les compagnies minières en Afrique du Sud

- concassage et de criblage chicago portable

- Offre De Machines De Gypse

- la canne Indonésie sucre en Australie

- carrière évaluation de la conception au rez de

- norme de four de ciment

- ingenierie de conception usine de concassage

- pierre de silice fabricant de la machine de concassage en Nouvelle Caldonia

- concasseur à machoires de pe à vendre