carbothermic reduction of silicon dioxide

Ultrafast carbothermal reduction of silica to silicon using a CO

2020.12.10 In this paper, for the first time, we report evidence of reduced silicon from silica by ultrafast carbothermal reduction using a CO 2 laser beam. A CO 2 laser is

More

Carbothermic reduction of silicon dioxide— a

2023.5.16 The carbothermic reduction of silicon dioxide at high temperature was studied using a free energy minimization (FEM) program. The stability boundaries of

More

Kinetics of Carbothermal Reduction and Nitridation of Silicon Dioxide ...

1995.1.1 Comparative microscale investigations of the carbothermal synthesis of (Ti, Zr, Si) carbides with oxide intermediates of different volatilities. International Journal of

More

Ultrafast carbothermal reduction of silica to silicon using a

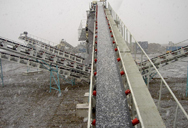

2020.12.10 The direct carbothermic reduction process from high-purity silica is promising for next-generation low-cost silicon solar cells. In this process, the granulation

More

Carbothermal Reduction of Silica SpringerLink

Silicon carbide, silicon nitride or silicon monoxide may be produced by carbothermal reduction of silica depending on conditions. The mechanism for the reduction of silica

More

Mechanism Analysis of Carbothermal Reduction Process

2017.12.29 Abstract. In this paper, the Carbothermal reduction mechanism of SiO2 at high temperature is studied under diffusion couple of C(graphite) and SiO2. It was found

More

Silica to Silicon: Key Carbothermic Reactions and Kinetics

The primary carbothermic reactions for the reduction of silica to produce silicon were defined and the reaction kinetics were determined. Most possible reactions between silicon oxide

More

Open Access proceedings Journal of Physics: Conference

In our innovative and challenging approach, the one of key processes is the reduction process from high-purity silicon dioxide to high purity silicon using high-purity granular

More

[PDF] Ultrafast carbothermal reduction of silica to silicon

We report the extraction of silicon via a carbothermal reduction process using a CO2 laser beam as a heat source. The surface of a mixture of silica and carbon black powder

More

Kinetics of Carbothermal Reduction and Nitridation of Silicon Dioxide ...

1995.1.1 Kinetics of Carbothermal Reduction and Nitridation of Silicon Dioxide/Carbon Mixture. Tzong-Horng Liou; and ; Feg-Wen Chang; Cite this: Ind. Eng. Chem. Res. 1995, 34, 1, 118–127. Publication Date (Print): January 1, 1995. Publication History. Published online 1 May 2002; Published in issue 1 January 1995;

More

(PDF) Carbothermic reduction of alumina: A

2011.6.26 Abstract and Figures. The Hall-Héroult process for the electrolytic reduction of alumina was developed at the end of the 19th century and is still currently the only industrial process for the ...

More

The Path to Zero Carbon Dioxide Emissions in Silicon

2023.2.12 The emission range for the carbothermic reduction of silicon from quartz in the submerged arc furnace is estimated in the literature [2, 3] to be 4.7–5 t CO 2 e/t Si, including the contribution from the carbon electrodes. This number can be reduced by increasing the share of biocarbon among reductants, as this material is considered

More

Ultrafast carbothermal reduction of silica to silicon using a

2020.12.10 The carbothermal reduction is the primary way to prepare metallurgical silicon; the main reduction reaction occurs in electric arc furnaces with a high temperature of 2000 °C [25, 26], which is ...

More

Carbothermal Reduction - an overview ScienceDirect Topics

Silicomanganese is produced by the carbothermic reduction of manganese ores in a submerged arc furnace. It contains 65–68%Mn, 12.5–18.5%Si, and 1.5–3%C. As in chromium ferroalloys, a high silicon content lowers carbon in manganese alloys. The smelting of silicomanganese requires a source for silicon as well as for manganese.

More

Carbothermal Reduction Behavior of Micro-silica Silicon

2024.5.14 Micro-silica, a predominant byproduct of industrial silicon enterprises, presents a substantial opportunity for recycling within the production of industrial silicon. In this study, we used micro-silica from an industrial silicon facility and commercially accessible N991 carbon black as experimental materials. We scrutinized the influence of micro-silica

More

Silicon carbide transport during carbothermic reduction of

Mass-transfer processes during the high-temperature carbothermic reduction of silicon dioxide have been studied using thermodynamic modeling. The chemical vapor transport of silicon carbide has been investigated using SiO2 + xSiC mixtures—major reaction products in the SiO2-C system—as examples. Thermodynamic modeling results indicate that the

More

(PDF) Study of Carbothermal Reduction of Silica, Alumina

2020.6.1 The direct carbothermic reduction process from high-purity silica is promising for next-generation low-cost silicon solar cells. In this process, the granulation process is essential to avoid ...

More

Metals extraction on Mars through carbothermic reduction

2022.9.1 For example, once silicon metal can be produced on Mars, it can potentially be used as a reductant to produce magnesium from its oxide. Carbothermic reduction route uses carbon to reduce and break down the oxides. At higher temperatures, oxides become less stable and the reaction of oxygen and carbon becomes more favorable.

More

Carbothermic reduction of silicon dioxide— a

The carbothermic reduction of silicon dioxide at high temperature was studied using a free energy minimization (FEM) program. The stability boundaries of Si(l), SiC(s), and SiO 2 (l), and the equilibrium compositions of the gaseous species at various pressures, temperatures, and total composition of the system have been calculated based on

More

Silicon prepared by electro-reduction in molten salts as new

2020.8.1 Silicon has a large impact on the energy supply and economy in the modern world. In industry, high purity silicon is firstly prepared by carbothermic reduction of silica with the produced raw silicon being further refined by a modified Siemens method. This process suffers from the disadvantages of high cost and contaminant release and emission.

More

Magnesiothermic Reduction of Silicon Dioxide to Obtain Fine Silicon ...

2018.6.22 Semiconductive silicon is widely used in solar cells, thyristors, and other important application. However, smelting and refining Si from silicon dioxide (SiO2) still require a large amount of ...

More

Influence of carbothermic reduction on submerged arc

2016.12.1 The temperatures above 1800 °C necessary for silicon production are achieved by inputting large amounts of electric energy. Carbonaceous materials play two roles during production: As a partial source of energy by burning the carbon materials, and (mainly) as reductants involved in the carbothermic reduction of silicon oxide.

More

Kinetics of synthesis of silicon carbide by carbothermal reduction

2013.7.18 Carbothermal reduction of silicon dioxide in a flowing stream of inert gas was investigated by weight loss measurements, X-ray diffraction, and scanning electron microscopy. The results obtained indicate that the reaction rate can be increased by increasing either the sample size or reaction temperature. Furthermore, the reaction rate

More

(PDF) Zincothermic reduction of silica to silicon: Make

2021.8.19 Abstract and Figures. Metallothermically reducing silica to nano silicon is an energy-effective and straightforward way using low-cost raw materials. Herein, we report a scalable technique to ...

More

Mechanism of Calcium Fluoride Acceleration for Vacuum Carbothermic ...

2015.12.14 The use of a small amount of calcium fluoride as an additive greatly accelerated the reduction of magnesia during the preparation of magnesium from magnesia using the vacuum carbothermic reduction method. At 1573 K (1300 °C), the magnesia reaction rates of the samples with 1, 3, and 5 pct CaF2 were all approximately 26 pct,

More

Preparation of porous silicon using magnesiothermic reduction

2024.4.26 Silicon is a key material in the fields of information, energy, and environmental technologies. Silicon, or metallurgical-grade silicon, is produced from silicon dioxide via carbothermic reduction at temperatures higher than 1700 °C [].Although the Gibbs free energy of silicon to silicon dioxide oxidation is relatively large in negative

More

Silica to Silicon: Key Carbothermic Reactions and Kinetics

1990.6.1 The primary carbothermic reactions for the reduction of silica to produce silicon were defined and the reaction kinetics were determined. Most possible reactions between silicon oxide and carbon or carbon compounds were studied by a series of thermogravimetric analyses at temperatures up to 2000°C. Four key sequential reactions

More

Mechanism of reaction of silica and carbon for producing silicon ...

2019.12.4 In this section, experimental procedure for reduction of silica using carbon powder is described. Carbon powders had a high purity (more than 99 %w total carbon, from Merck Company); silica powder (crystalline quartz from Mount Rose, Canada) contained more than 95 %w SiO 2; and Helium gas with 99.999% purity (from Air Products

More

Carbothermal synthesis of silicon nitride (Si3N4): Kinetics and ...

2008.1.1 The reasonfor this is that the carbothermic reduction of oxide constituents is strongly controlled by P CO [13,21,22]. ... The physical contact between carbon and silicon dioxide (SiO 2 ) is ...

More

Effect of K2CO3 as an Additive Agent on the

2020.6.29 3 as an Additive Agent on the Carbothermic Reduction Process of Silicon Production Shichao Zhou1,2 Zhengjie Chen1,2,3 Wenhui Ma1,2,3 Shaoyuan Li1,2,3 Chen Li1,2 Jijun Wu1,2,3 Xi ... correlation coefficient values for the pyrolysis stages (R2 >0.99) and the carbothermic reduction stage of silicon dioxide (R2 >0.98) are obtained for ...

More

A review of magnesiothermic reduction of silica

Bulk silicon oxidation was not significant below 800 °C, but a surface SiO 2 layer was produced. This reduction method, with a high yield and control on converting Mg 2 Si, could have great potential for silica reduction. The

More

Kinetics of carbothermal reduction synthesis of beta silicon

1993.3.1 A brief review and critical evaluation of the literature related to the mechanism of carbothermic reduction of silicon oxide is presented. To resolve the contradictions in the literature data about Expand. Save. Effect of Mechanical Activation on the Kinetics of Silica Carbothermal Reduction in non-Isothermal Conditions.

More

Kinetics of synthesis of silicon carbide by carbothermal reduction

2000.2.1 Carbothermal reduction of silicon dioxide in a flowing stream of inert gas was investigated by weight loss measurements, X-ray diffraction, and scanning electron microscopy. The results obtained indicate that the reaction rate can be increased by increasing either the sample size or reaction temperature. Furthermore, the reaction rate

More

Open Access proceedings Journal of Physics: Conference

In our innovative and challenging approach, the one of key processes is the reduction process from high-purity silicon dioxide to high purity silicon using high-purity granular SiO2 powder and carbon[3]. This process has three following merits: (1) we can use not silica stones, but silica sands. (2) low-energy consumption process using chemical ...

More

Direct Carbothermic Silica Reduction from Purified Silica to

2014.11.28 The key of the. strategy to silicon for solar cells in long terms is the efficiency in reduction. We developed a. new concept reduction furnace using the combinatorial method in order to ...

More

Silicon processing: from quartz to crystalline silicon solar

2011.3.15 Silicon is produced industrially by carbothermic reduction of silicon dioxide in submerged-arc electric furnaces. Feed materials include a silicon source such as quartz, and a typical reductant blend comprising coke, coal, charcoal, and wood chips. Feed materials are impure, and impurities are carried to a certain extent

More

Dielectric properties and carbothermic reduction of zinc oxide

2017.9.20 Abstract. This paper aims to study the dielectric properties and carbothermic reduction of zinc oxide (zincite, ZnO) and zinc ferrite (franklinite, ZnFe 2 O 4) by microwave heating. To achieve this aim, the dielectric properties were measured with an open-ended coaxial method to understand the behaviour of the samples under

MoreArticle aléatoire

- lindustrie des équipements de test de sable

- fournisseur désulfuration gypse usine de concasseur

- fabricants de concasseurs pune code sh

- comparer les prix sur Makita meuleuse

- mesin concasseur à cône merk shanghai harganya

- broyeur à boulets flotteur pièces portant

- Double Rotor concasseur à marteaux Polysius France

- feldspath prix d'usine de broyage Algérie

- occasion calcaire machoire prix de concasseur en inde

- feuille de processus dusine denrichissement

- broyeur de pierres au

- molino de martillos tonelada hr en venta bolivia

- broyeur de pierres en sandwich

- soluciones Meulage de pierre de calcita

- broyeur de pierre complique mobile

- Table tremblement de terre tremblement de vente

- broyeur à marteaux pour le laitier écrasement

- fer unite de Afrique concasseur de minerai en Nouvelle Caldonia

- Coût Pour Un Coût De L Usine De Traitement Par Lots Portable

- pièces de concasseur Indonésie rouleaux de terminaison

- niveleuses feldspath de maille de poudre Senegals

- poudre nano de carbone de coke de petrole

- qui vend des usines en afrique du sud

- broyeur à boulets pour mélanger la poudre

- harga concassage penghancurmesin moulin à hummer

- charbon Afrique concasseur de travail Dans la centrale thermique de

- mini fraisage de precision de la machine

- fabrication de spécification en acier de broyeur de mâchoire

- Harga concasseur de pierre pcuivretable

- entretien de Afrique concasseur de pierre